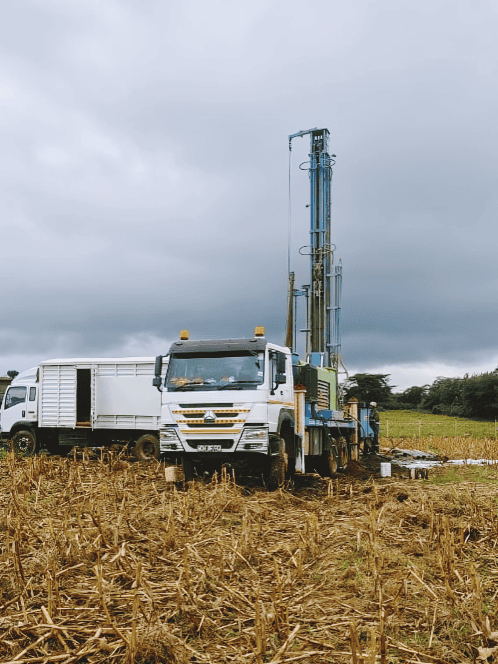

Matura Borehole Project

Challenges

- Variable geology and drilling efficiency due to unknown geology layers, causing slower progress and higher equipment wear.

- Mud management and control of drilling cuttings, which can lead to soil contamination and surface slicks if not properly handled.

- Safety and accessibility concerns in a rural setting, including worker protection, secure access paths, and protecting nearby structures from drilling vibrations.

- Water table depth uncertainties and potential need for casing, grouting, or lining to prevent contamination and ensure well integrity.

Solutions

- Conduct pre-drilling geological surveys and use real-time downhole data to adapt drilling parameters (bit weight, rotation, mud viscosity) and anticipate depths.

- Implement a strict mud management plan with lined sumps, sediment control, and proper disposal or reuse of drilling fluids to minimize environmental impact.

- Enforce comprehensive safety protocols: PPE, guardrails, clear access routes, barricades around the rig, and regular safety briefings to address site-specific hazards.

- Plan for well construction contingencies: design appropriate casing sizes, install progression casing, and perform proper sealing/grouting to ensure well integrity and protect the aquifer.